Antibacterial Polyester Four-Way Stretch Fabric Fundamentals: Technology and Functional Synergy

The modern textile industry is characterized by the convergence of aesthetics and advanced functionality, and Antibacterial Polyester Four-Way Stretch Fabric stands as a prime example of this synthesis. This specialized material is engineered to meet the rigorous demands of activewear and performance apparel, integrating three critical functions into a single substrate: microbial control, dynamic elasticity, and synthetic durability. The polyester component provides inherent advantages such as excellent moisture resistance, quick-drying capabilities, and structural resilience against wear and tear. Crucially, the incorporation of four-way stretch , typically achieved through the knitting or weaving structure combined with elastane (spandex)—ensures the fabric moves seamlessly with the wearer, offering unrestricted range of motion and superior comfort necessary for intense physical activity. This mechanical stretch differentiates it from two-way stretch materials by allowing elasticity in both the warp and weft directions, optimizing fit and minimizing restriction across all planes of movement. The antibacterial property, which is vital for odor control and hygiene, is achieved either through surface finishes or, more durably, by embedding antimicrobial agents (such as silver ions or copper) directly into the polymer matrix during the fiber extrusion process. This synergistic combination of properties positions this fabric as a high-value material, particularly for applications where comfort, hygiene, and performance are equally prioritized across long periods of use and frequent washing cycles, driving its dominance in niche segments like high-end athletic wear and specialized uniforms.

The key functional pillars of this material are:

- Four-Way Stretch: Provides maximum mobility and shape retention, achieved via specialized elastane inclusion and knitting patterns.

- Antibacterial Efficacy: Inhibits the growth of odor-causing bacteria and fungi, enhancing hygiene and reducing laundry frequency.

- Polyester Durability: Ensures quick moisture release (quick-drying) and resistance to wrinkles, pilling, and UV degradation.

- Thermal Regulation: The moisture-wicking and quick-drying nature help in maintaining a comfortable body temperature during high exertion.

Target Market: Antibacterial Polyester Four-Way Stretch Fabric for Athleisure

The rapid globalization of the athleisure market—where performance features are blended with everyday style—has created exceptional demand for high-utility textiles. The suitability of Antibacterial Polyester Four-Way Stretch Fabric for athleisure is unparalleled, as it satisfies the core consumer requirement for garments that can transition seamlessly from a workout session to a casual social setting. The four-way stretch provides the comfortable, body-contouring fit that is characteristic of modern activewear, while the antibacterial function ensures that odors are neutralized, eliminating the need for immediate changing post-exercise. Furthermore, the polyester base delivers easy-care properties; these garments are lightweight, resist wrinkling, and dry quickly, aligning perfectly with the low-maintenance, high-mobility lifestyle that athleisure embodies. For brands targeting this consumer segment, the fabric is not just a material but a core marketing asset, emphasizing health, convenience, and long-term freshness. This strategic fit underscores why the fabric has become indispensable for leggings, fitted tops, and travel apparel.

Performance requirements dictated by the athleisure trend:

- Style and Fit: High-quality stretch and recovery are necessary to maintain the garment's shape and aesthetic appeal.

- Odor Management: The antibacterial feature must be highly effective to allow multi-use wear between washings.

- Easy Care: Quick drying and wrinkle resistance are critical convenience factors for busy lifestyles.

Performance Life Cycle: Durability of Antibacterial Polyester Four-Way Stretch Fabric Washing

A primary concern for B2B buyers is the Durability of Antibacterial Polyester Four-Way Stretch Fabric washing, as the performance longevity directly impacts product quality perception and customer satisfaction. The durability of the antimicrobial effect is fundamentally determined by the application method. There are two general approaches: additive finishes and inherent integration. Additive finishes, applied after the fabric is woven or knit, are typically less expensive but can wash out over time, leading to diminished antibacterial efficacy after 20 to 50 wash cycles. In contrast, inherent integration , where the antimicrobial agent (e.g., silver) is locked within the fiber matrix during polymerization, offers a permanent solution that lasts the lifetime of the garment, often achieving 99% efficacy even after 100 industrial washes. When sourcing, buyers must specify the application type and request supporting technical data to ensure the fabric meets the expected performance life cycle, especially for products like medical scrubs or durable athletic gear designed for extended use.

Comparison of antibacterial application methods:

| Application Method | Mechanism | Durability in Washing | Cost Implications |

| Additive Finish (Topical) | Coating applied post-production | Low to Medium (Washes out over time) | Lower Initial Cost |

| Inherent/Integrated | Agent embedded in polymer matrix | High (Permanent, lasts garment life) | Higher Initial Cost |

Quality Control and Sustainable Sourcing Benchmarks

Verification Standards: How to test Antibacterial Polyester Four-Way Stretch Fabric efficacy

For any material claim to be valid, it must be supported by verifiable, standardized testing. Knowing How to test Antibacterial Polyester Four-Way Stretch Fabric efficacy is essential for quality control and compliance professionals. The two most recognized international standards for testing antimicrobial activity on textiles are AATCC 100 (quantitative) and JIS L 1902. The AATCC 100 method measures the percentage reduction of specific bacteria (typically *Staphylococcus aureus* and *Klebsiella pneumoniae*) after a set incubation period on the treated fabric. A result demonstrating a 99.9% reduction (or a $\geq 3.0\text{ log reduction}$) is generally considered effective. The JIS L 1902 standard similarly quantifies the bactericidal activity. Importantly, professional buyers must also specify testing before and after a prescribed number of wash cycles to confirm the Durability of Antibacterial Polyester Four-Way Stretch Fabric washing. These reports are crucial regulatory documents for market entry in many jurisdictions and serve as non-negotiable proof of performance for the customer.

Key standards for antibacterial validation:

- AATCC 100: Quantitative test method for the evaluation of antibacterial finishes on textile materials.

- JIS L 1902: Standard for antimicrobial activity and efficacy testing on textile products.

- ISO 20743: International standard for determination of antibacterial activity of textiles.

Eco-Sourcing: Recycled Antibacterial Polyester Four-Way Stretch Fabric wholesale price and GRS Certification

The convergence of function and sustainability has led to strong market preference for Recycled Antibacterial Polyester Four-Way Stretch Fabric wholesale price and its associated certifications. This material is made using rPET (recycled polyethylene terephthalate) derived from post-consumer plastic waste, significantly reducing the reliance on virgin petroleum resources and lowering the carbon footprint of the final garment. When assessing the Recycled Antibacterial Polyester Four-Way Stretch Fabric wholesale price, buyers should factor in the cost of certifications like the Global Recycled Standard (GRS). GRS verification ensures transparency and traceability, confirming that the stated percentage of recycled content is accurate and that social and environmental criteria were met during manufacturing. While recycled materials may initially carry a small premium over conventional polyester, the long-term benefits of compliance and the strong market appeal of sustainable sourcing often justify the added expense, especially for brands prioritizing corporate social responsibility.

Impact of sustainability on procurement:

- GRS Certification: Verifies the recycled content and ethical processing, adding integrity to the supply chain.

- Lower Environmental Impact: Appeals to eco-conscious consumers and meets brand sustainability targets.

- Price Volatility: Cost is tied to the availability and processing of post-consumer plastic waste, separate from petrochemical markets.

Commercial Strategy: Sourcing and Cost Management

Price Structure: Factors Influencing Recycled Antibacterial Polyester Four-Way Stretch Fabric Wholesale Price

The final Recycled Antibacterial Polyester Four-Way Stretch Fabric wholesale price is determined by a confluence of technical specifications, market dynamics, and volume. Key price variables include the percentage of recycled content, as GRS-certified rPET often trades at a slightly higher base price than generic polyester. The elastane content is also a major driver, as Spandex/Lycra is a high-cost component; higher four-way stretch percentages directly increase the material cost. Furthermore, the type of antibacterial treatment is crucial: inherent silver-ion technology is significantly more expensive than a chemical post-finish, reflecting the difference in Durability of Antibacterial Polyester Four-Way Stretch Fabric washing. Finally, as with most B2B textile transactions, the order volume (MOQ) plays a crucial role; larger commitments allow Antibacterial Polyester Four-Way Stretch Fabric manufacturers and suppliers to achieve better economies of scale, leading to a more favorable per-yard or per-meter price for the buyer.

Core elements affecting wholesale pricing:

- Elastane Percentage: Higher stretch ratio equals higher cost.

- Antibacterial Technology: Inherent embedding is costlier than topical finishing.

- Recycled Content: GRS-certified rPET adds a premium for traceability.

- Minimum Order Quantity (MOQ): Negotiability based on order size and annual volume.

Supply Chain Vetting: Selecting Antibacterial Polyester Four-Way Stretch Fabric Manufacturers and Suppliers

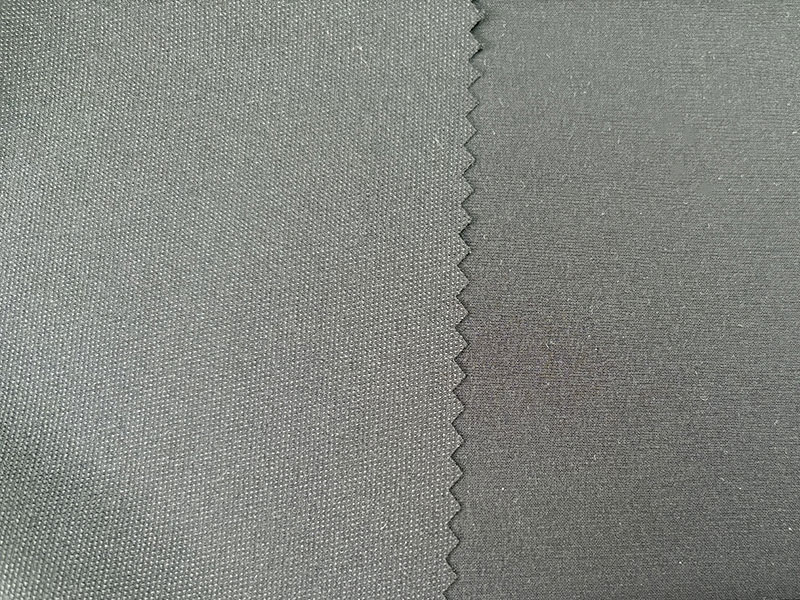

Successfully sourcing requires stringent evaluation of potential Antibacterial Polyester Four-Way Stretch Fabric manufacturers and suppliers. Beyond competitive pricing, buyers must verify the supplier's technical competence in two specific areas: complex knitting/weaving of four-way stretch materials and specialized chemical treatments. A reliable supplier must provide verifiable testing reports (AATCC 100) and regulatory compliance documents (e.g., EU Biocidal Products Regulation, TSCA) for the antibacterial agents used. Manufacturers who handle both the textile production and the finishing/treatment in-house often offer better quality control and faster lead times. Prioritizing suppliers with GRS certification demonstrates a commitment to sustainable sourcing, providing a crucial competitive advantage in the finished product market. Always request sample swatches and test reports to confirm the Durability of Antibacterial Polyester Four-Way Stretch Fabric washing before committing to a bulk order.

Critical evaluation criteria for suppliers:

- R&D Capabilities: Ability to customize stretch levels and antibacterial concentration.

- Compliance: Verification of all biocidal agents used against global safety and environmental lists.

- Testing Facilities: Proof of in-house quality assurance and third-party validation reports for stretch and antibacterial efficacy.

FAQ

Is the Antibacterial Polyester Four-Way Stretch Fabric for athleisure application safe for sensitive skin?

Yes, high-quality Antibacterial Polyester Four-Way Stretch Fabric for athleisure is generally considered safe for sensitive skin, provided the manufacturer adheres to strict chemical safety standards. The primary concern relates to the leaching of topical antibacterial finishes. Reputable Antibacterial Polyester Four-Way Stretch Fabric manufacturers and suppliers utilize embedded technologies (like silver ions) or ensure that any surface finish is non-toxic and compliant with standards like Oeko-Tex Standard 100, which specifically tests for harmful substances. When sourcing, always request Oeko-Tex certification to guarantee the textile is free from sensitizing or toxic residues, ensuring both high performance and skin compatibility for the end-user.

How does the Durability of Antibacterial Polyester Four-Way Stretch Fabric washing impact bulk purchasing decisions?

The Durability of Antibacterial Polyester Four-Way Stretch Fabric washing is a key factor in calculating the long-term value and effective Recycled Antibacterial Polyester Four-Way Stretch Fabric wholesale price. Buyers should prioritize yarns with integrated antibacterial technology, despite the higher initial cost, because they guarantee efficacy for the garment's entire lifespan (50+ washes). Choosing cheaper topically treated fabric, which loses its function after fewer washes, results in a product with a shorter functional life, leading to poor customer reviews and higher return rates. Therefore, investing in durable, integrated technology is a strategic choice that improves product quality perception and reduces hidden long-term costs.

What are the critical steps in How to test Antibacterial Polyester Four-Way Stretch Fabric efficacy to ensure a high-quality product?

The critical steps in How to test Antibacterial Polyester Four-Way Stretch Fabric efficacy involve selecting the appropriate international standard (e.g., AATCC 100 or JIS L 1902) and testing against relevant target organisms (*S. aureus* and *K. pneumoniae*). Crucially, the test must be performed on the fabric both before and after the specified number of wash cycles (e.g., 20 or 50 standard washes) to verify the Durability of Antibacterial Polyester Four-Way Stretch Fabric washing. A quality test report should document the "log reduction" ($\geq 3.0\text{ log}$ is ideal, representing a 99.9% reduction) for each organism. This dual testing procedure is essential proof for both regulatory compliance and marketing claims regarding the fabric's long-term hygiene performance.

English

English 中文简体

中文简体

.png)